PIEZOELECTRIC COMPOSITIONS AND PIEZOCERAMIC COMPONENTS

PIEZOELECTRIC COMPOSITIONS

Centre for Materials for Electronics Technology (C-MET) , Thrissur has developed the following piezoceramic compositions which are engineered for enhanced electromechanical properties. Different standard compositions, as shown below are available. C-MET also has the capability for custom-made Piezoelectic compositions to suit the requirement of a particular application.

Standard Piezoelectric compositions

|

Sl No |

Product |

Code |

|

1 |

Piezoelectic composition |

PZT-H1 |

|

2 |

Piezoelectic composition |

PZT-H2 |

|

3 |

Piezoelectic composition |

PZT-S1 |

|

4 |

Piezoelectic composition |

PZT-S2 |

The important properties of standard piezoceramics offered by C-MET are given in Table 1 given below.

Table 1 Specifications of Standard Piezoelectric Compositions

|

Electrical Characteristics

|

PZT-H1

|

PZT-H2

|

PZT-S1

|

PZT-S2 |

||

|

1 |

Dielectric Permittivity ,er

|

1430 |

1120 |

1743 |

2682 |

|

|

2 |

Dielectric loss ,tan d

|

0.003 |

0.002 |

0.02 |

0.02 |

|

|

3 |

Piezoelectric Coefft.d33(pC/N)

|

355 |

328 |

456 |

630 |

|

|

4 |

Electromechanical coupling factor ( kp)

|

0.59 |

0.58 |

0.64 |

0.65 |

|

|

5 |

Mechanical quality factor Qm

|

685 |

900 |

72 |

70 |

|

|

6 |

Density (gm./cc)

|

7.6 |

7.6 |

7.7 |

7.6 |

|

|

7 |

Frequency constant,N Hz.-m

|

2083 |

2100 |

1900 |

1975 |

|

|

8 |

Curie Point, Tc(0C) |

330 |

330 |

360 |

272 |

|

PIEZOCERAMIC COMPONENTS

C-MET has the capability to fabricate Components of various shapes. Quality system ISO 9001: 2008 is in place to ensure reproducibility and traceability. Typical dimensions and some of the important properties of piezoceramic components offered by C-MET are given in Table 2.

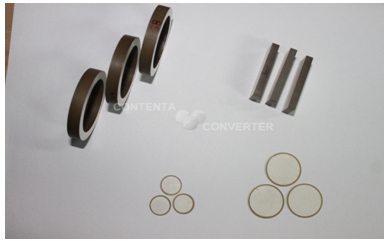

Piezoceramic Components – PZT Rings, PZT Plate and PZT Discs

Advantages

- Lower sintering temperature

- High-density microstructures

- Enhanced electromechanical properties

- Improved Insulation Resistance(IR) in Components

Table 2. Specifications of Piezoceramic Components

|

Piezoceramic component |

Typical dimensions |

Electrical Characteristics |

|||||

|

C(nF) |

tan δ |

d33 (pC/N) |

fr (KHz) |

keff |

IR (GΩ) |

||

|

PZT Ring |

OD = 50.00±0.05mm ID = 38.00±0.10mm t = 8.00 ±0.08mm

|

1.15±0.04 |

0.002 |

325±25 |

179±1 |

0.58±0.02 |

150±25 (1000V DC) |

|

PZT Disc

|

Dia = 15.04±0.06mm T = 0.28 mm

|

10.50±0.50 |

0.02 |

520±20 |

135±1 |

0.65±0.02 |

20 (100V DC) |

|

PZT Disc

|

Dia = 24.70±0.20mm T = 1.03±0.03mm

|

10.0±1.0 |

0.02 |

575±30 |

81.75±0.75 |

0.56±0.02 |

20 (100V DC) |

|

PZT Plate

|

Length = 40.00± 0.03 Width = 19.94±0.02 Thk = 5.00 ±0.01 |

1.60±0.07 |

0.002 |

275±50 |

394±2 |

0.58±0.02 |

110±10 (1000 V DC)

|